Early Background

University Life

Career Summary

Global Projects

| |

Richard

Stitt

25+ years Senior

Manufacturing Engineer /Senior Project Manager

with experience in

Aerospace,

Consumer Electronic & Automotive Manufacturing

Previous

Responsibilities and Accomplishments:

Sr.

Manufacturing Engineer

EXTENSIVE

RECORD OF IMPACTFUL

MANUFACTURING LEADERSHIP IN DEMANDING SETTINGS

Highly

technical, quality-focused engineer with extensive experience designing,

building, testing and implementing enterprise-wide systems against aggressive

requirements. Analytical strategist skilled in gathering, analyzing and

translating product specifications into on-time deliverables. Collaborative

communicator focused on leading teams and building relationships with vendors,

staff and senior management to drive engineering excellence.

Key Skills:

|

§

Engineering

Processes

§

Project

Management

§

Capacity

Analysis Planning

§

Quality

Assurance

|

§

Manufacturing

& Tooling

§

Inventory

& Cost Control

§

Line

Balancing

§

Team

Training & Leadership

|

§

Compliance

§

Industrial

Safety

§

Strategic

Planning

§

Communications

|

Professional

Experience Professional

Experience

LTI

MO, KS, MI

Consulting Engineer

10/2014 - Current

Consulting Engineer / Senior Project Engineer / Program Manager

7/1997 – 12/2012

Handpicked

to design proprietary manufacturing techniques and processes for $234M

technology transfer project aimed at enhancing general aviation product line.

Built and maintained business plans and financial models.

Key

Achievements & Engagements

- Achieved 900% reduction in

flight vibration levels through development of improvement process;

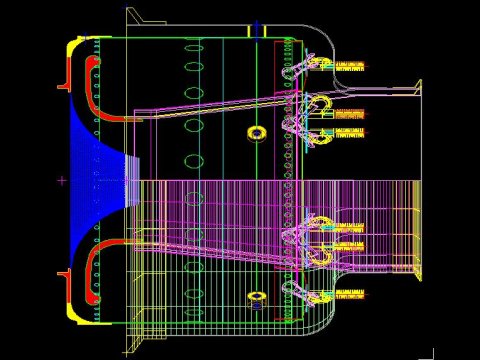

- Developed new style

high-efficiency gas turbine engines with 35% system thermal efficiency;

- Designed and built new tooling

applications and specifications for automated

equipment lines;

- Concurrently led major

projects, training & development efforts and continual improvement

efforts;

- Identified and resolved

technical and procedural deficiencies through expert troubleshooting and

analysis

- Developed new modular insert

tooling processes for complex automated robotic fiberglass assemblies.

DANA HOLDINGS (AEROTEK CONTRACT)

MI

Senior Consulting Engineer / Senior Industrial Engineer

2/2013 – 4/2014

Progressed

from temporary new hire to current leader of special initiatives with

responsibilities spanning project management, contractor coordination, internal

tool audits, strategy setting and quality assurance monitoring.

Key

Achievements & Engagements

- Executed relocation and merger

of two active manufacturing sites separated by 45 miles;

- Selected to maintain and

strengthen contract relationships with Ford;

- Completed all capacity analysis

reports (CAR), OEE analysis, Control Plan, PPAP, Process FEMA &APQP;

- Coordinated internal tool

audits for Ford and Chrysler;

- Team member Dana’s 5S, Root

Cause Analysis, Quick Response and Kaizen quality systems.

- Devised and deployed

improvement initiatives, apply lean mfg principles,

- Earned Excellence in Service

Award, 2013

Early

Career

SII, GM

Cadillac Engine 4.1, 4.5, 4.9 Validation Project Engineer

Liberty, MO SII, GM

Cadillac Engine 4.1, 4.5, 4.9 Validation Project Engineer

Liberty, MO

LIBBY WELDING, TQ Production Testing Engineer /

Supervisor

KC, MO

SII, Design & Production of Electronic

Assemblies, Contract Mfg/ Project Engineer

KC, MO

Key

Achievements & Engagements

-

Develop

and Implement Business Plans and Financial Models

-

Executed relocation and merger

of two active manufacturing sites separated by 45 miles

-

Selected to maintain and

strengthen contract relationships with Ford

-

Completed and disseminated all

capacity analysis reports (CAR) and OEE analysis.

-

Coordinated internal tool

audits for Ford and Chrysler

-

Devised and deployed

improvement initiatives, apply lean mfg principles

-

Earned Excellence in Service

Award, 2013

-

Develop

and Implement Business Plans and Financial Models

-

Develop

Green Power Point Presentation developed for Large OEM’s to conceptualize

new innovations of the Plastic Industry for product weight savings and fuel

efficiency for new and upgraded products.

-

Develop

new ways to continuously train and monitor employee’s knowledge base and

document levels of training and certifications levels by the use of custom

multi language internet training software.

-

Take

pride and ownership of custom production lines and processes developed for

OEM clients.

-

Coordinate

Project activities for Inside and Outside Engineering staff,

-

Develop

new proprietary manufacturing processes, automated equipment, tooling and

software controls.

-

Lead

large projects, new designs, and capital equipment purchases, with 234

million currently under Technology Transfer Contract Review.

-

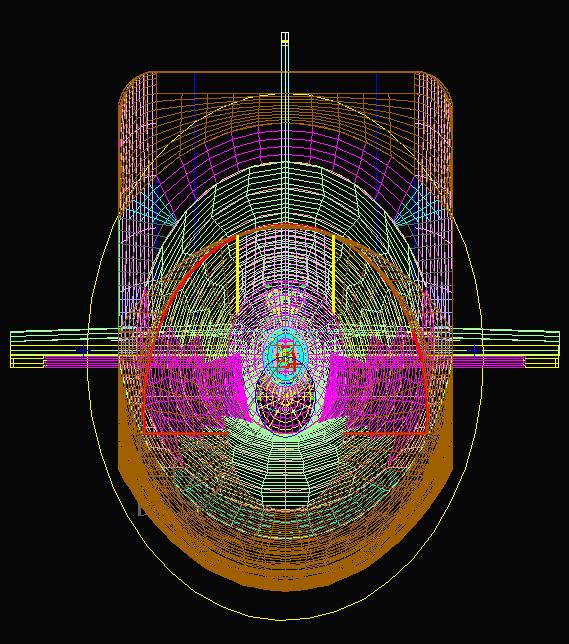

Design

and build specifications for new automated equipment lines and custom laser

measuring tools.

-

Investigates

and make recommends for new manufacturing methods and technologies.

-

Experienced

in developing budgets, increasing productivity, reduced scrap, reducing

labor cost by 30 to 50%.

-

Developing

new style high efficiency gas turbine engines with overall system thermal

efficiency approaching 55% using university software simulators based on the

Brayton Cycle.

-

Solving

complex manufacturing process issues thru effective coordination of outside

vendor involvement by 3rd party validation testing.

-

Design

and build custom mechanical assemblies for new product evaluation

-

Design

and build custom electrical circuit including PCB layout of digital and RF

circuitry

-

Provide

leadership and training as needed to technicians and manufacturing personnel

-

Partner

with sales team for new business development

-

Interact

with sales and quality assurance departments providing support in resolving

issues dealing with the customer, production, or supply chain, Good problem

solving ability using TQM and 6 Sigma

-

Provide

ongoing "lifetime" support of product in regards to its

manufacture date.

-

Create

or oversee the generation of fixture designs and work instructions for

manufacture of product

-

Design

of test processes and test automation for evaluation of custom designs

-

Develop

Technical Specifications and Reports

-

Self-starter

and able to manage multiple programs

These photos link to other product pages

|